Chemical pump in the face of corrosion what needs attention

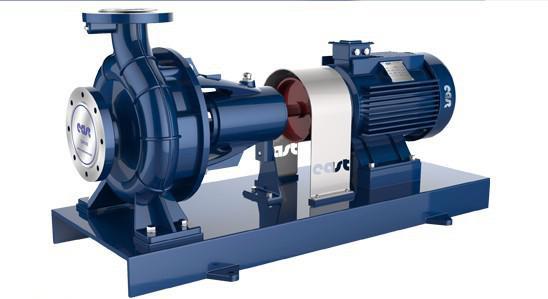

The principle of pump selection, in the selection of Centrifugal pump model so that the correct determination of Centrifugal pump material is to ensure the safe operation of centrifugal pumps and prolong the service life of an important factor.

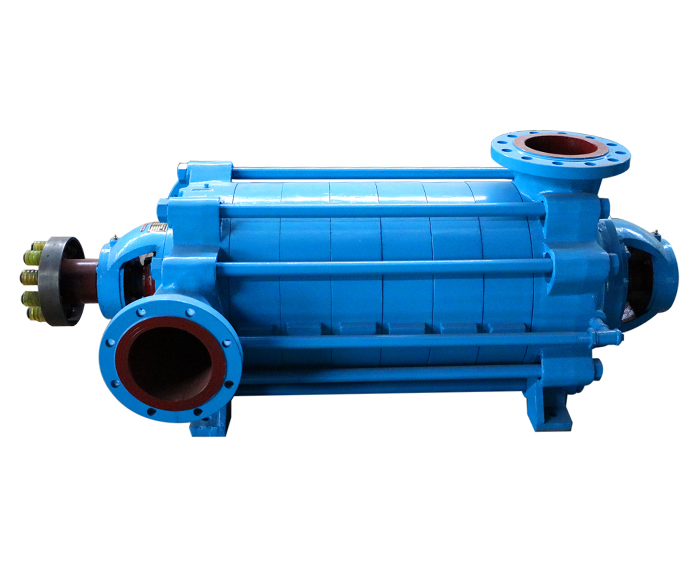

Chemical pump in the face of corrosion which needs attention. 1. The principle of pump selection, in the selection of Centrifugal pump model so that the correct determination of Centrifugal pump material is to ensure the safe operation of centrifugal pumps and prolong the service life of an important factor. In order to select the most suitable material, the influence of various factors should be considered comprehensively from many aspects. (1) the nature of the pump medium and pump operating conditions, such as temperature, pressure, corrosion, viscosity, whether or not containing solid particles. In addition, we have to consider whether there are other special circumstances, such as medicine, food industry requirements conveying medium especially clean, to prevent metal ion pollution, conveying the pump containing solid particles medium material requirements such as good wear resistance. (2) the Mechanical Properties of the material shall be suitable for the requirements of the pump. There are many indexes to reflect the mechanical properties of the material. The strength, rigidity, hardness, plasticity, impact toughness and fatigue resistance of the material are considered. (3) the processing performance of the material is directly related to the manufacture, installation and overhaul of the pump. Centrifugal pump impeller, Shell, balance disc and most of the parts are cast from metal materials, and then mechanical processing, some parts also need heat treatment. The processing properties of materials also directly affect the use of materials and the cost of the pump. (4) whether the corrosion resistance is good or not is an important problem which can not be ignored in the selection of pump materials. For the petrochemical industry, the corrosion resistance of the pump is particularly important. 2. Commonly used anti-corrosion pump material selection, petrochemical production often encountered acid, alkali and other corrosive liquid materials on metal materials. The centrifugal pumps used to transport such materials are collectively called corrosion-resistant centrifugal pumps. The types of these pumps are represented by F. their working principles are similar to those of centrifugal water pumps, its corrosion resistance is mainly determined by the nature of the materials used to manufacture such pumps. Most corrosion-resistant pumps can be corrosion-resistant mainly depends on the flow parts of the pump material, corrosion-resistant pumps, according to the different delivery media, select the flow parts of the pump material. For example, 1Cr18Ni9Ti can be used in low concentration nitric acid and other oxidizing acid liquid, alkali liquid and weak corrosion medium at normal temperature: 0Cr18Ni12Mo2Ti is most suitable for transporting high concentration nitric acid at normal temperature, but also can transport sulfuric acid, organic acid and other reducing medium: Gray cast iron HT200 is suitable for concentrated sulfuric acid; Plastic has a wide range of applications, polytetrafluoroethylene and polyperfluoroethylene propylene and other materials after a reasonable formula, molding, processing, plastic anti-corrosion pump has a strong anti-corrosion performance, and with high mechanical strength, aging, non-toxic decomposition, and other advantages, is the ideal transport of a variety of strong and weak acids, polytetrafluoroethylene is one of the best corrosion-resistant materials, basically resistant to any acid, Alkali corrosion media, known as the plastic king. Ceramics, Enamel, glass and other special occasions are also used to make corrosion-resistant pump parts of the flow.