Characteristics and installation of axial flow pump

Zlb pump is a single-stage vertical axial flow pump, with liquid flowing along the axial direction of the pump. This type of water pump has low lift and large flow, which is suitable for sucking and delivering clear water or other liquids with similar physical and chemical properties.

Characteristic:

Zlb pump is a single-stage vertical axial flow pump, with liquid flowing along the axial direction of the pump. This type of water pump has low lift and large flow, which is suitable for sucking and delivering clear water or other liquids with similar physical and chemical properties. The maximum temperature of the liquid is 50 ℃, mainly used for farmland drainage and irrigation, industrial thermal power station to deliver circulating water, urban water supply and drainage, dock water level rise and fall or other water engineering water, and its application range is very wide.

Installation and use:

1. Check whether the pump shaft and transmission shaft are bent during transportation, and straighten them if any.

2. The installation elevation of the water pump must be in accordance with the provisions in the installation drawing to meet the requirements of NPSH and startup.

3. Trash rack shall be set before water entering the pool to avoid sundries with water inlet pump. The velocity of water passing through the trash rack shall not exceed 0.3 M / s.

4. Before the installation of water pump, it is necessary to check whether the installation angle of blade meets the requirements and whether it is loose.

5. After installation, check whether the nuts of each coupling and each foot bolt are tightened. When tightening the nuts on the transmission shaft and water pump shaft, pay attention to the thread direction.

6. The transmission shaft and pump shaft must be installed on the same vertical line, and the tolerance is less than 0.03 mm / m.

7. Gate valve should not be installed on the outlet pipe of water pump. If so, it must be fully opened before starting.

8. When using the check valve, it is better to install a balance weight to balance the weight of the valve cover, reduce the resistance of water outlet, and make the pump run more economically.

9. Lubricate the bearing of transmission device with lubricating grease. During maintenance, the oil chamber shall be removed and cleaned, and then refilled with lubricating grease. The amount of lubricating grease shall be 1 / 2 ~ 2 / 3 of the oil chamber, so as to avoid too high temperature rise of bearing during operation. Special attention must be paid that the rubber bearing must not touch the oil.

10. Before starting the water pump, water or soapy water shall be introduced into the short pipe at the upper packing culvert to lubricate the rubber or plastic bearing, and it can be stopped after the water pump operates normally.

11. Before each start of the water pump, the coupling shall be turned for three or four revolutions first, and attention shall be paid to whether there is any imbalance in weight. If there is, the cause must be checked, and the operation shall be carried out after elimination.

12. Before starting, check the rotation direction clicked to make it conform to the water pump rotation direction, and then connect with the water pump.

13. When the water pump is running, the following points should be paid attention to regularly:

Whether the immersion depth of impeller is enough, i.e. whether the water inlet level is too low, so as not to affect the flow or generate noise.

Whether there is friction between the outer circle of the impeller and the impeller shell, whether there are sundries around the blade, whether the rubber or plastic bearing is too tight or burnt, so as to avoid the increase of shaft power.

Whether the fastening bolts are loose and whether the center of pump shaft and transmission shaft are consistent to prevent vibration of the unit.

- No contents!

-

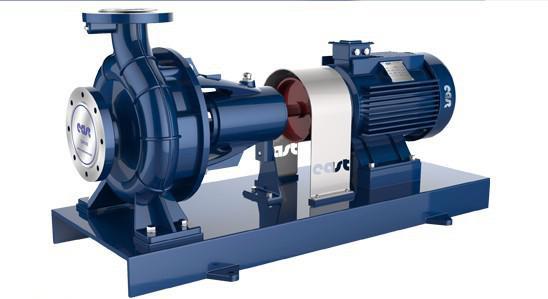

Next:Usage of horizontal centrifugal pump